01

I started prototyping the most important mechanism of the dispenser: the cannon. I tested multiple prototypes and methods of firing. Using inexpensive materials like foam core, and popsicle sticks, I was able to create a successful proof of concept. At the same time, I identified numerous issues that needed addressing in the next prototypes.

02

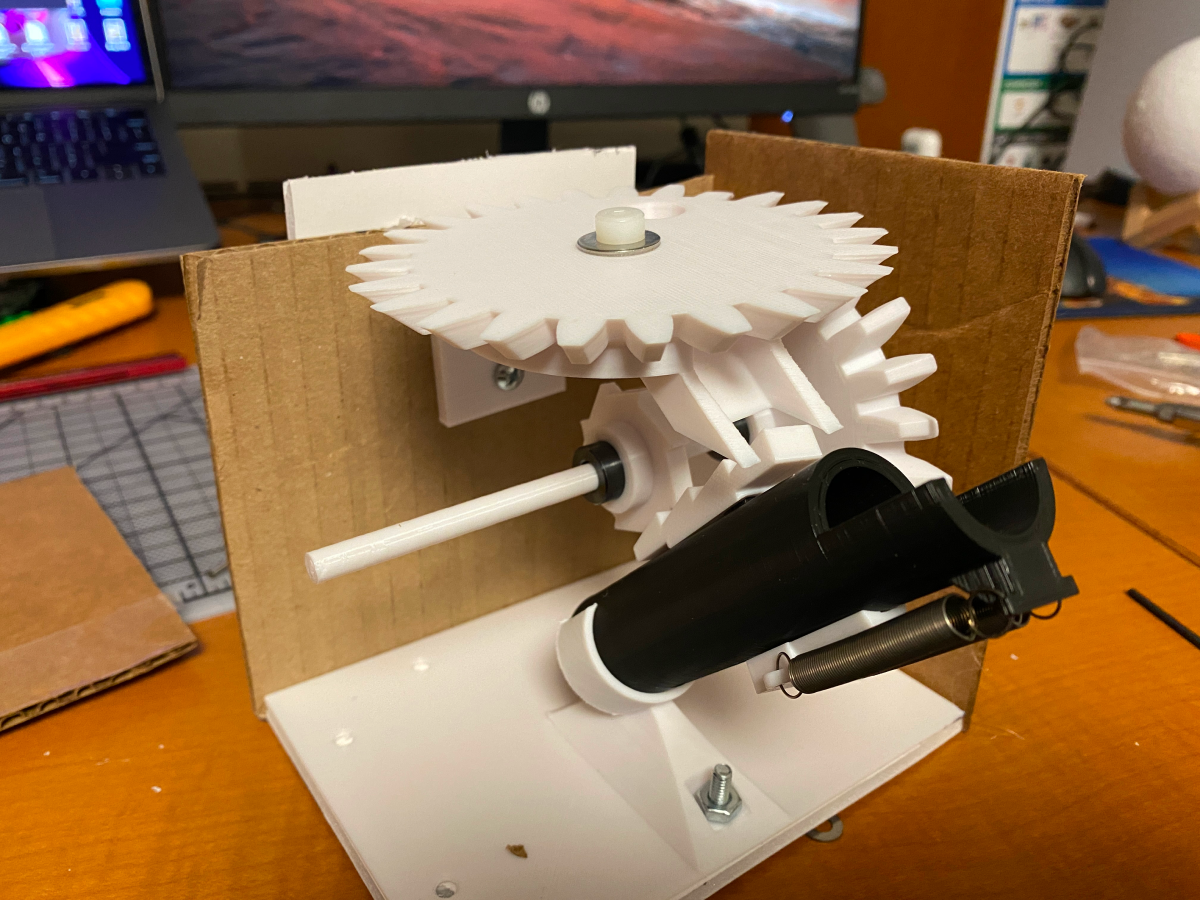

In order to more accurately test the dispenser's capabilities, I had to create my

first mechanism prototype. Though the pieces seemed compatible, there were still major issues with the firing

mechanism— issues like rotation and movement that wouldn't have been identified without a complete set.

03

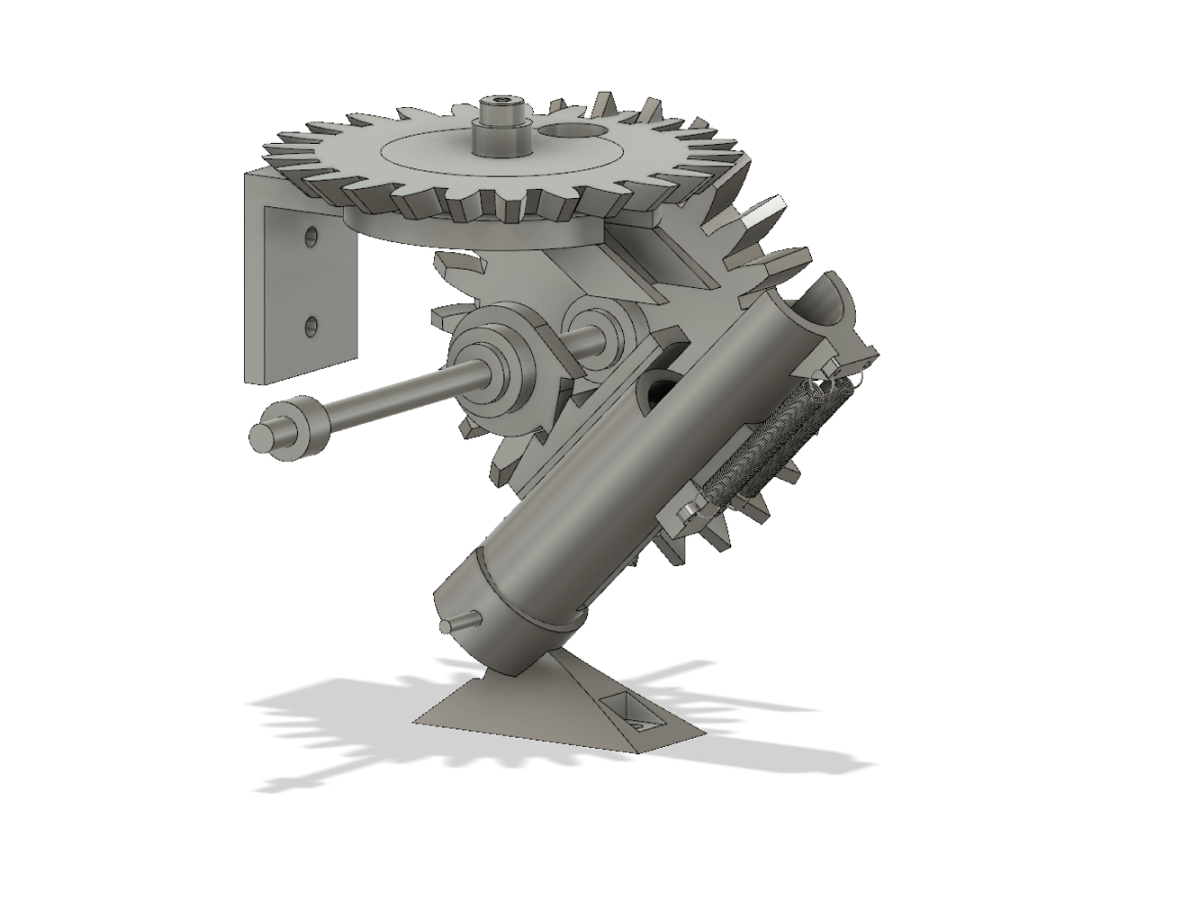

After experimenting with the cannon stability and the rack and pinion, I was able to create a consistent cannon dispenser. It took several prints to get the size and shapes right.

The complete CAD model of all functioning parts are shown here.

04

I created an enclosure and funnel to complete the dispenser. It works reliably and continuously

as I turn the knob— every rotation is an M&M fired.

With over 25 iterations of working parts, this project was extremely reliant on prototyping. It taught me so much about iterative testing and the importance of CAD modeling.